Real sustainability will be measured through emerging carbon metrics and financial cost. So, what are the considerations that will be evaluated for whole-of-life UPS operation. From installation through commissioning to maintenance – what is missing from conventional cost analysis? Listen to our fireside chat to learn more on how we are paving the way.

In the energy intensive data centre sector real sustainability means evaluating 25 year whole-of-life UPS operation. Fresh thinking and asking the right questions about components, manufacturing, installation, maintenance and ultimately recycling are needed. Do do you know the true carbon cost of your UPS technology choice? This fireside chat between Ambrose McNevin, former editor of DatacenterDynamics, and Keith Maclean-Martin of Piller UK takes a deep dive into sustainability and asks: What is missing from conventional cost analysis?.

For every organisation energy sustainability considerations are changing. At a power infrastructure level sustainability will be measured through a combination of carbon measurement metrics and financial cost.

Achieving true sustainability in any company that uses large amounts of electricity needs to be assessed as a short, medium and long term goal. As a critical part of the power chain operating over decades, it is vital to understand what needs to be evaluated for whole-of-life UPS operation.

This means understanding a new set of risks and opportunities.

The following fireside chat hosted by Digital Infrastructure Network explores how life cycle analysis from installation through to operation is common but in a changing business and regulatory environment to address what is missing from conventional cost analysis.

Ambrose McNevin, Managing Director of Tech Marketing Content, journalist and former editor of Data Centre Dynamics, speaks with Keith Maclean-Martin Technical Manager at Piller UK Ltd.

Ambrose McNevin: In order to explore the sometimes overlooked aspects of UPS investment, ownership and operation In the context of sustainable infrastructure how has risk been redefined?

Keith Maclean-Martin: To date client’s think of risk in terms of financial and technical, with little or no mention of sustainability.

This cannot be the case anymore.

Risks must be viewed in measured carbon costs in new and emerging sustainability, metrics, methods, standards and financial outcomes. Importantly this is about long-term whole of life calculations. It has been the case that even when making long term infrastructure investments people are not very good at thinking in decades, which is the typical working life of the equipment.

Worldwide regulatory bodies have guidance to deliver sustainable energy to all businesses. These include IEEE 1547 for the integration of renewable energy to the grid. The soon to be recast European Energy Directive which includes a drive to make buildings more energy efficient.

With the world staring over a cliff edge for the environment, failure to adopt the correct metrics and methods to meet emerging emissions and efficiency standards could result in tariffs and in the worst cases heavy penalties.

Ambrose McNevin: Let’s explore that a little further – what are the factors that are in play?

Keith Maclean-Martin: Sustainability should be assessed in three stages covering the Whole life Carbon Impact, much as financial assessments do with Whole Life Cost.

The carbon prior to installation; the carbon during use; and the carbon after use to recycle and dispose. By far the most significant and overlooked stage is the carbon during use.

Ambrose McNevin: OK, so are people thinking enough about the carbon cost of Maintenance and MTTR?

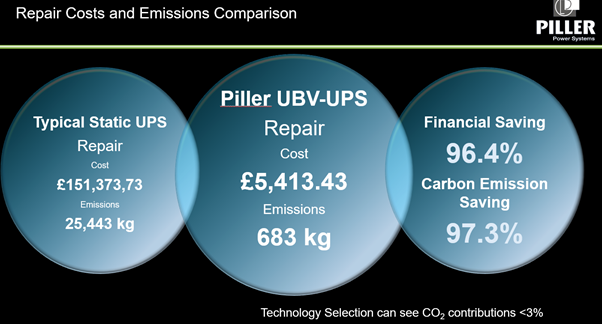

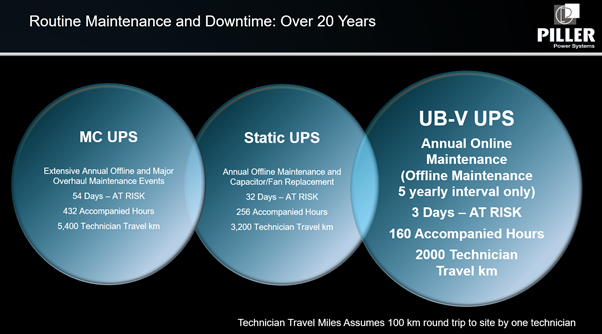

Keith Maclean-Martin: Equipment lifetimes can be as much as 25 years. The carbon for maintenance might appear obvious – but in areas such as component replacements, and fault attendances. There is carbon to be factored into all these components and additional visits.

Every break fix incurs a carbon cost which includes site visit logistics, and just as importantly component manufacture and supply chains. With advances in technology, some UPSs complete power assemblies are regularly changed to rectify a fault – these are then shipped back to the manufacturer for repairs and then shipped back to site as a service replacement.

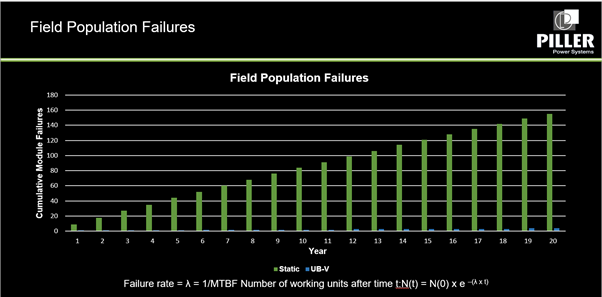

Field Population Failures

Ambrose McNevin: How is this really a sustainable philosophy?

Keith Maclean-Martin: Equipment sustainability needs to be viewed through the lens of how the operational carbon will be impacted by the reliability of equipment which suffers frequent failures requiring more attendances and component replacements.

Routine Maintenance and Downtime: Over 20 Years

Ambrose McNevin: Should we not look to deliver sustainability through reliable quality equipment?

Keith Maclean-Martin: We can expect that the sustainability agenda will mean energy intensive industries can expect new energy use and efficiency audits by reporting regimes to become part of their everyday operations.

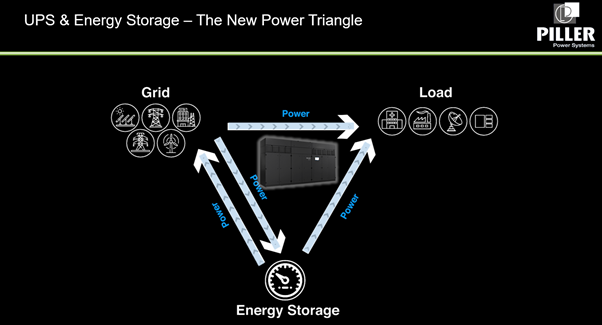

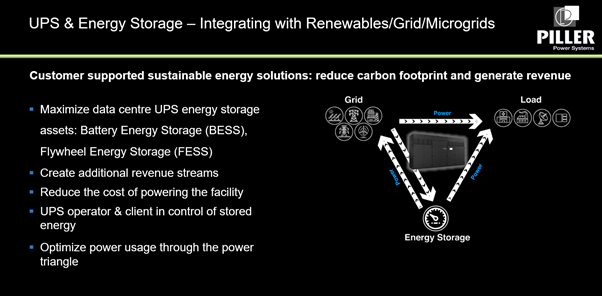

Ambrose McNevin: What is the new Power Triangle?

UPS Power Storage – the Power Triangle

Keith Maclean-Martin: Power infrastructure was designed to flow in one direction from the grid incomer and follow a linear path to the load.

Simplistically, this is how the National Grid was designed with power leaving the power stations flowing through the grid to the point of use.

The introduction of renewable generation and energy storage at the point of use changed the power flow and complicated the model. System operators across the world have acknowledged that Invertor Based Resources (IBRs), transmission and distribution is only going to become more complex.

The original power triangle allowed the energy storage to power the load when there was no grid available.

The new power triangle introduces power flows from the energy store directly to the grid. This offers huge opportunity for facilities to support the National Grid to deliver sustainable power.

Ambrose McNevin: Why is it relevant to cost – carbon and financial – calculations?

Keith Maclean-Martin: Data centres have installed huge infrastructure that includes embedded generation and energy storage capacity. Such power capacity is rarely used to more than a fraction of its design intent to protect the critical load. The opportunity exists to utilise some of this asset, without increasing the components’ carbon impact thus reducing a site’s carbon impact.

There are different models to achieving this such as reducing the energy used from the grid during times of peak capacity or even providing real power to the grid that can be used by others.

UPS & Energy Storage – Integrating with Renewables/Grid/Microgrids

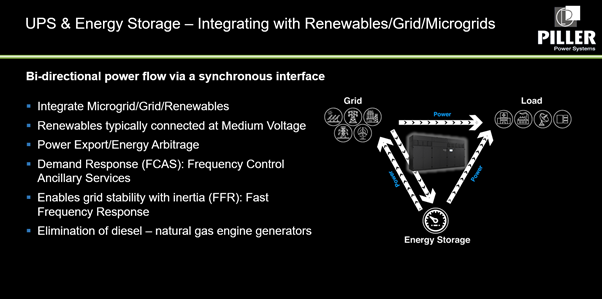

Ambrose McNevin: Why is UPS infrastructure important in providing Demand response and dispatchable power?

Keith Maclean-Martin: Grid operators know they must carefully balance the use of intermittent renewable generation while maintaining a sufficient reserve to cater for dynamic changes.

As they shift their focus to network infrastructure and planning the transition onto a sustainable energy future. Grid system operators are already evaluating the use of dispatchable power through Demand Side Response services that allow greater flexibility in how the grid is managed.

There are circumstances when renewable generation may need to be disconnected as it cannot be used or stored which would only destabilise the network.

Data centres with the right UPS infrastructure in place can participate in these services, earning revenues and supporting the National Grid to deliver the most sustainable power possible.

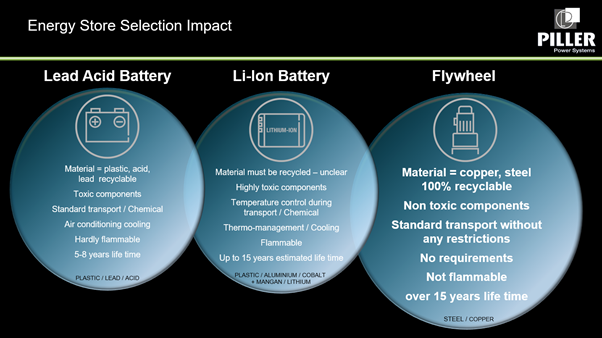

Ambrose McNevin: Energy storage is key – can it be sustainable?

Keith Maclean-Martin: Energy storage certainly plays a key role in delivering sustainable goals at all levels of infrastructure. The develop of different battery chemistries will drive how sustainable these products are.

Energy Store Selection Impact

However, we must remember they also require an inverter to deliver power to Grid utilising electronic devices. Although shared with the UPS these devices must be factored into the reliability metrics and carbon usage.

In the long term, new technologies will emerge which might include solid state batteries, green hydrogen powered fuel cells where the hydrogen is produced from spare RE capacity or fingers crossed nuclear fusion.

There could be a time when existing technologies are redundant. We cannot simply wait for these technologies to be developed and deployed at scale. That means we must make the best sustainable power infrastructure decisions today as this is key to delivering near and long term sustainability now and over the coming decades.

Ambrose McNevin: We must address energy sources and applications such as Microgrids – what’s the role of the UPS?

UPS & Energy Storage – Integrating with Renewables/Grid/Microgrids

Keith Maclean-Martin: As facilities grow, we see power infrastructure moving outside of the data centre. The development of Microgrids allows the integration of multiple renewable generation sources, decarbonising the energy being used. The UPS will play a vital role in managing the power quality and the balance of generation sources supporting the load.

Microgrids, whether islanded or integrated are developing rapidly. The UPS can also play a unique role to isolate and reduce the risk of disturbances if the National Grid affects site operations.

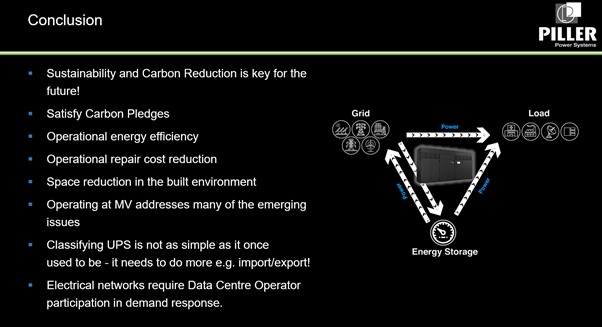

Ambrose McNevin: How important are Whole of Life ROI calculations to cost analysis in a changing power landscape?

Keith Maclean-Martin: The power landscape is changing very rapidly with a 65% decrease in emissions achieved between 2013 and 2020. The National Grid has significant targets over the next 10 years to achieve the targets announced by government policy. This will see Grid Power Generation decarbonised, delivered with zero fossil fuel generation by 2035.

As governments around the world introduce new policies and set new targets, how we use this energy will be subject to tighter and tighter regulations. This could see penalties levied against frivolous operations wasting natural resources.

Investment in the right infrastructure now will allow the support of the national goals, help big power users more easily integrate with utility partners while benefiting from incentives and potentially avoiding carbon penalties in the future. This is the basis for true end to end and whole of life financial and sustainable UPS ROI.

ENDS.

About Piller

Piller was founded in Hamburg, Germany in 1909 by engineer Anton Piller. Employing around 1000 people worldwide, Piller is headquartered in Osterode, near Hanover, Germany, with subsidiaries across Europe, America, Asia and Australia. Piller occupies a unique position, being the only company to produce both types of electrically coupled UPS technologies and with kinetic energy storage or battery options. The company also manufactures aircraft ground power units, 50/60Hz frequency converters, static transfer switches and specialist marine generators. With more than 7000 kinetic energy storage devices and over 6000 high power UPS units installed, Piller has more than 300 service personnel taking care of clients across 24 countries. The Piller group is a wholly owned subsidiary of the multi-disciplined global UK engineering and industrial group, Langley Holdings Plc. In 2016, Piller acquired Active Power Inc., the flywheel energy storage specialist. Piller Power Systems is part of Langley’s Power Solutions Division.